Products and Services

Erysense Technology

Engineering

and Hardware Development

Microfluidics Development and Production

Microfluidics Development and Production

At Cysmic, our expertise lies in the development and fabrication of cutting-edge microfluidic devices that revolutionize the field of biomedical diagnostics. Microfluidics is a game-changing technology that allows us to manipulate and control fluids on a microscopic scale, typically below 100µm in size. This miniature dimension opens possibilities for precise and efficient fluid testing analysis.

Once the design is finalized, we embark on the transformative fabrication phase, where our cutting-edge technology comes to life. Our ability to fabricate microfluidic devices with structure sizes smaller than 10µm on an industrial scale sets us apart. We achieve remarkable accuracy and reproducibility through our expertise in injection molding, enabling mass production of microfluidic devices with exceptional precision. Moreover, our vast selection of polymers ensures we can tailor the device properties to meet specific requirements. With perfect optical quality and low birefringence, our polymers guarantee reliable and accurate results for various applications.

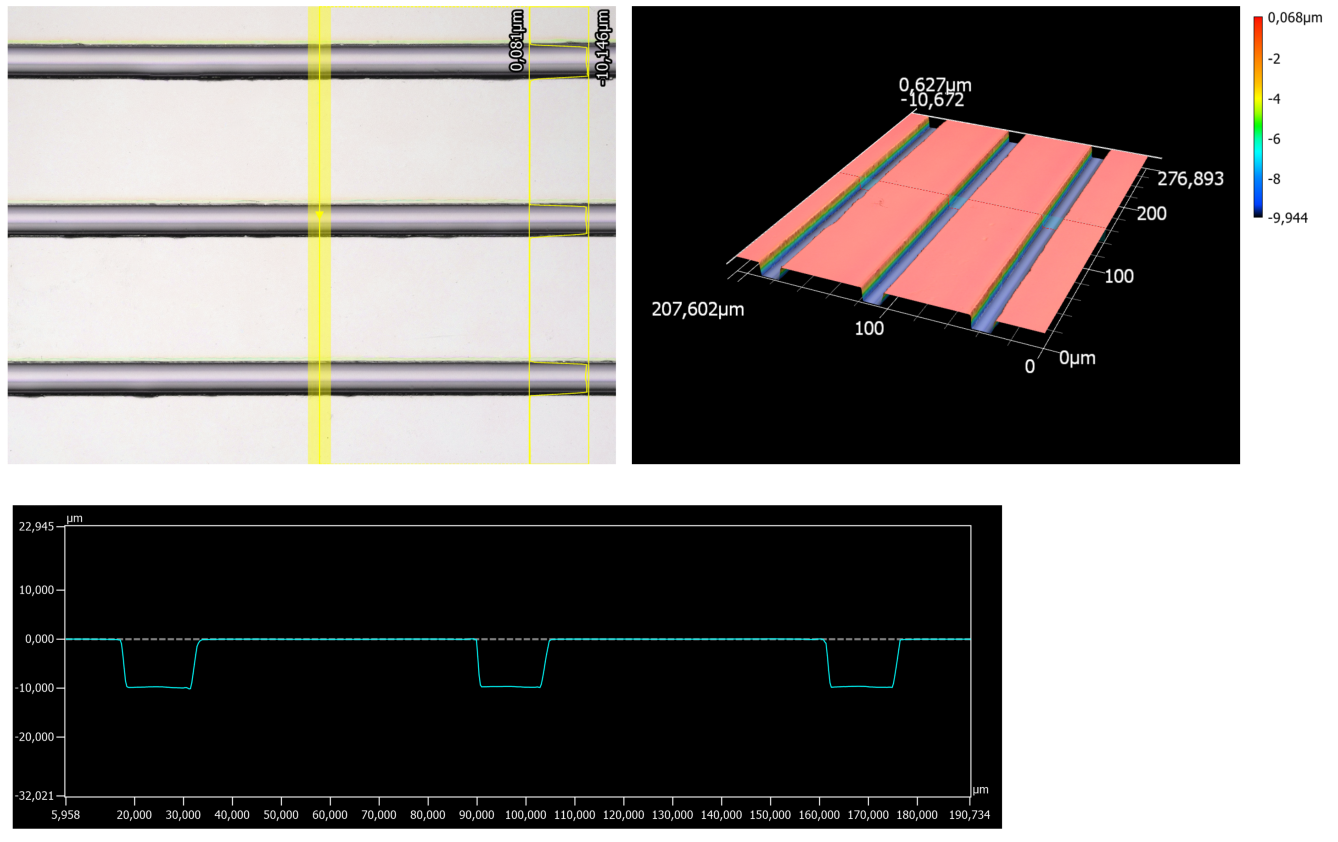

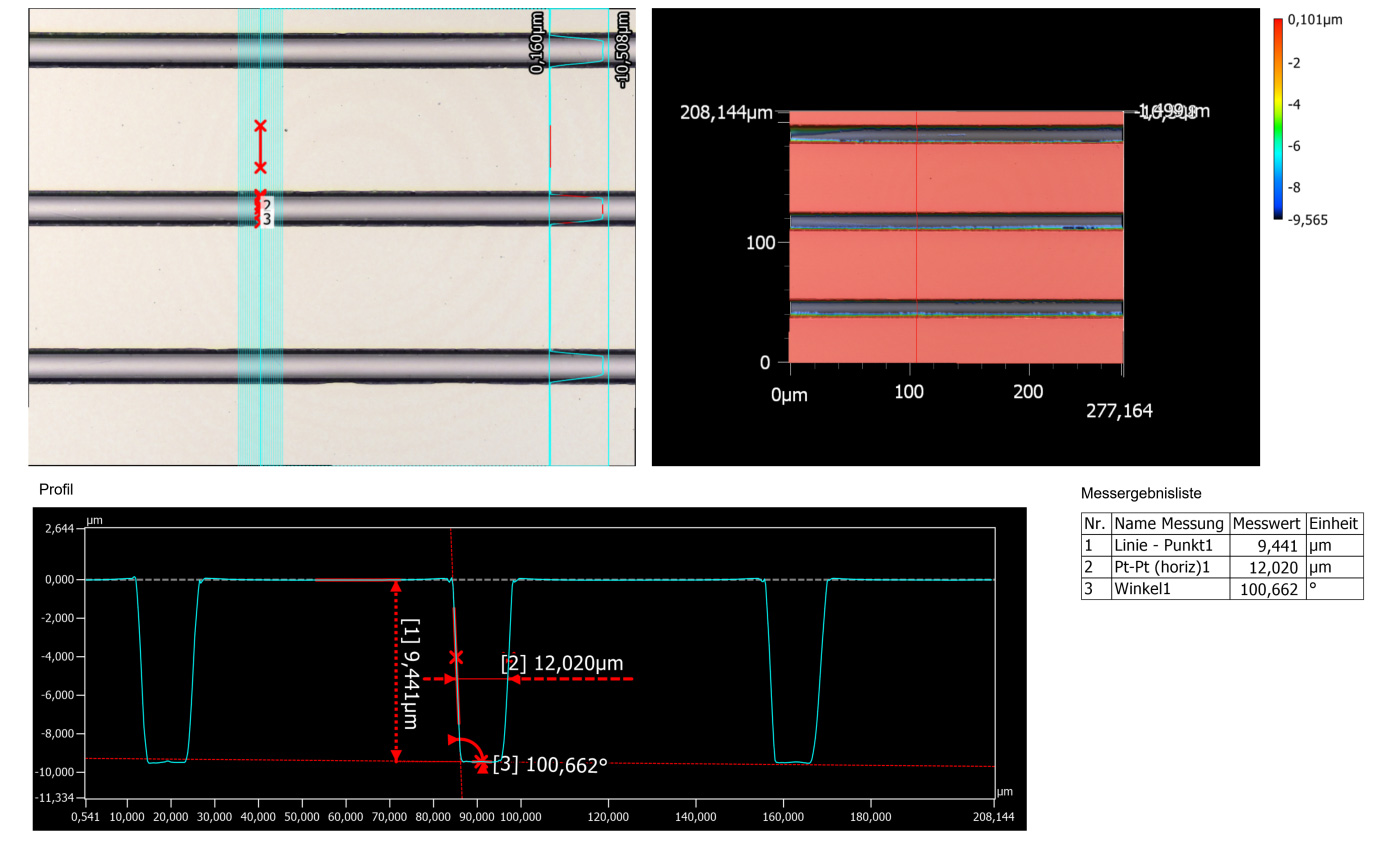

At Cysmic, we are committed to ensuring the highest precision and quality of our microfluidic chips. To validate and verify the accuracy of our chips, we employ state-of-the-art techniques, including cutting-edge 3D laser scanning microscopy. This methodology enables us to capture detailed images and measurements of the microfluidic structures at a microscopic level. This advanced imaging technique allows us to examine the intricate features and dimensions of the chips with exceptional precision and resolution. By generating three-dimensional representations of the microfluidic channels through measurements, we can thoroughly analyze and verify the integrity of the design. In addition to 3D laser scanning microscopy, we utilize a range of complementary techniques and quality control processes to ensure the precision and functionality of our microfluidic chips. These procedures include optical inspection, surface profilometry, and flow characterization tests. These techniques allow us to validate crucial parameters such as channel dimensions, surface smoothness, and fluid flow dynamics, ensuring that our chips meet stringent performance standards.

We use an in-house developed chip bonding technology that allows us to reliably and reproducibly seal chip substrates without destroying the channel structures and without affecting the optical quality of the bonding film. Since no adhesives or solvents are used, the process is easy and inexpensive to implement even for large quantities.

Partner with us for cutting-edge biomedical diagnostics solutions and discover our microfluidic devices’ unparalleled precision. Contact us today to explore the remarkable capabilities of our design and fabrication processes and discover how our microfluidic devices can elevate your biomedical diagnostics to unprecedented levels of performance and efficiency.

Contact

info(at)cysmic.de

Auf der Trift 1

66127 Saarbrücken